Our fabrication facilities include 2.000 m² where we house 8 state of the art CNC machines. The cutting-edge machines selection is lead by DMG MORI CMX 70U and DMG MORI EcoTurn 450 machines.

Machines

Reliability, accuracy and precision are at the foundation of every custom-engineered MOEK product. The high level of service is achieved with constant impro y and state-of-the-art machining tools and equipment.

Milling Machines

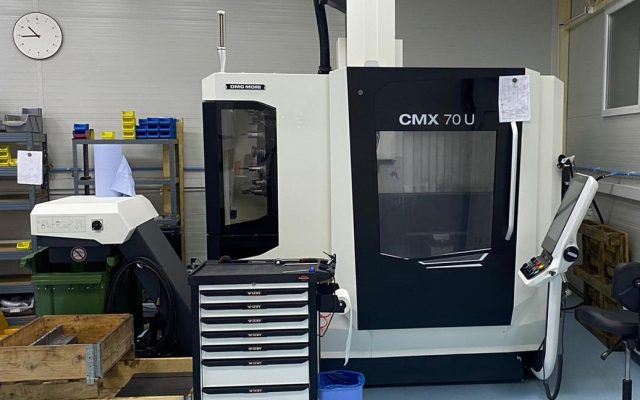

DMG MORI CMX 70U

5-sided machining with direct measuring system and IoTconnector in standard

- 5-axes milling

- Direct measurement system

- Max. X travels: 750 mm

- Max. Y travels: 600 mm

- Max. Z travels: 520 mm

Control & software alternatives

- SIEMENS HEIDENHAIN

Korradi Kempten

- Max. X travels: 800 mm

- Max. Y travels: 550 mm

- Max. Z travels: 500 mm

Machine Center OKK PCV-50

- Spindle speed 6000

- Max. X travels: 720 mm

- Max. Y travels: 520 mm

- Max. Z travels: 520 mm

Lathe

DMG MORI Eco Turn 450 JMG

- Max. turning diameter: 400 mm

- Max. work piece length with a tailstock (can be machined): 800 mm

- Max. chuck size: 315 mm

- Max spindle motor speed: 4,000 rpm

- Max. bar capacity diameter: 80 mm

Control & software alternatives:

- SIEMENS

HAAS HL2

- Turning Diameter (mm) 250mm

- Turning Length (mm) 500mm

- Max. X travels: 750 mm

- Max. Y travels: 600 mm

- Max. Z travels: 520 mm

HARDINGE COBRA 42

- Bar Capacity: 42 mm

- Spindle Speed: 4000 rpm

- Tools available: 12

- Max. X travels: 150 mm

- Max. Z travels: 150 mm

DAINICHI F25

- Spindle diameter: f65

- Spindle Speed: 3000 rpm

- Max. X travels: 300 mm

- Max. Z travels: 500 mm

- Tools: 16 pieces

Cutting

KASTOwin A 3.3

- Cutting range: 330 mm

- Smallest dimension to be cut: 10 mm

- Shortest length of residual piece, automatic operation: 60 mm

- Shortest length of cut-off piece: 10 mm

Measuring Tools

Tools used for the machines

The tools that are used in daily operations are standardized across the industrial park. They are maintained and timely serviced to be ready to use for requested project.

Engineering Software

Software

We believe precision engineering is critical to superior manufacturing and excellent results. Before fabrication we ensure the part is well engineered to function and precise specifications. Machining programing that are used in this process are Inventor, ProE and Siemens Sinumerik.